179

How to Streamline Inventory Management, Minimize Stockouts, and Optimize Warehousing Operations Using Odoo ERP?

5 min read

179

5 min read

Table of Content

Stockouts that are regular interrupt customer orders and erode trust, resulting in frustration to all parties. Meanwhile, depending on manual count results, most of the time in expensive errors and lost time.

Overcrowded and disorganized warehouses not only contribute to increased operational expenses but also slow down the entire supply chain. All these pose a real challenge to maintaining a smooth inventory flow and meeting demand effectively.

That is where Odoo inventory management has a definite edge. It offers real-time tracking of stock, which minimizes the threat of depleting vital items. Its warehouse management software solutions also enhance space utilization and automate order processing, eliminating avoidable delays.

All these features, combined, result in a trusted and effective inventory system that ensures smooth operations and satisfied customers.

|

Challenges |

Consequences |

|

Frequent stockouts |

Delayed customer orders and lost sales opportunities |

|

Manual inventory counting errors |

Inaccurate stock data leading to wrong orders and overstocking |

|

Poor warehouse space utilization |

Higher operational costs and slower order processing |

|

Lack of real-time inventory visibility |

Difficulty in timely decision-making and demand fulfillment |

|

Inefficient stock replenishment |

Increased risk of excess inventory or stock shortages |

|

Limited forecasting capabilities |

Poor demand planning causing supply chain disruptions |

|

Inability to integrate with other systems |

Fragmented data and inefficient workflow across departments |

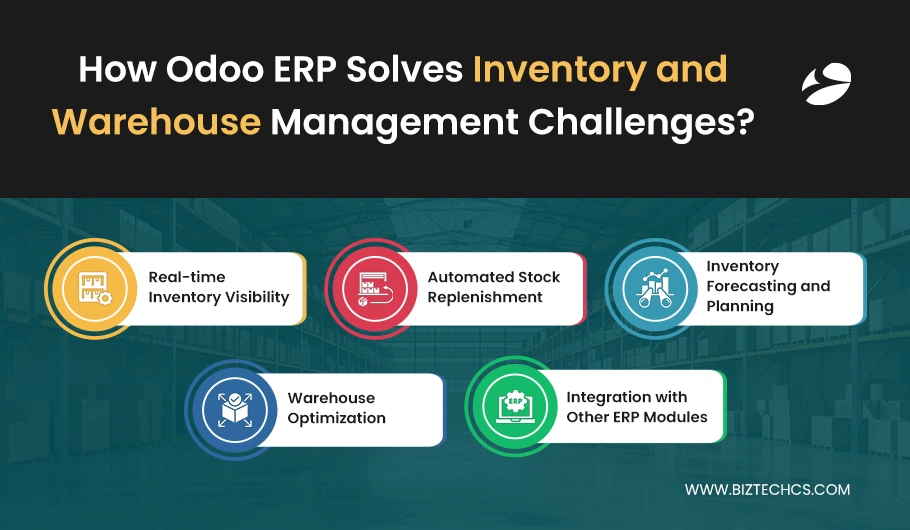

Real-time Inventory Visibility

Odoo ERP provides real-time inventory tracking across multiple locations. This implies that stock levels are precise and visible at any time. Real-time stock status updates enable teams to respond instantly to alterations.

This minimizes delays or stock mistakes. Odoo inventory management gives companies precise and up-to-date information at their fingertips. Real-time inventory tracking ensures smooth operations.

Automated Stock Replenishment

The system automatically triggers reorders of stock when stock levels drop below preset levels. This smart automation eliminates the need for manual checks. It preempts stockouts by providing timely replenishment.

It also prevents overstocking because it orders only what is required. Stock replenishment automation in Odoo maintains inventory levels in balance without persistent supervision. This streamlines supply chain management.

Inventory Forecasting and Planning

Odoo utilizes historical sales and inventory data to accurately predict demand. Its inventory forecasting tool examines trends to enable planning for future stock requirements. This minimizes excess stock and decreases holding costs.

Improved forecasting implies fewer surprises and more predictable stock availability. It enables companies to synchronize purchasing with actual customer demand. This results in wiser, data-informed inventory choices.

Warehouse Optimization

Odoo warehouse management software streamlines picking and packing operations to accelerate order fulfillment. It also supports the creation of optimized warehouse layouts to maximize space utilization. All these factors lower operational expenses through enhanced workflow and storage efficiency.

More accurate and quicker warehouse activities translate into customer satisfaction. The software breaks down complicated warehouse processes into manageable, simplified steps. This enhances overall warehouse productivity.

Integration with Other ERP Modules

Odoo integrates inventory management with sales, manufacturing, and procurement modules. This continuous integration enables all departments to access synchronized data. It minimizes errors generated by fragmented systems and enhances communications.

Orders and stock movements are monitored across functions in real-time. This integrated approach makes inventory operations more robust and transparent. It develops a cohesive system that enables effective workflows with the help of expert Odoo Integration services.

Reduced Stockouts

Odoo ERP prevents stockouts by utilizing automated triggers to maintain optimal stock levels. When stock is low, the system triggers reordering before supplies exhaust themselves. This eliminates lost sales and dissatisfied customers.

The capacity to control stock with accuracy maintains a smooth operation by avoiding operations breakdowns. It also saves time that would be wasted responding to shortages. Accurate inventory management ensures the business operates smoothly.

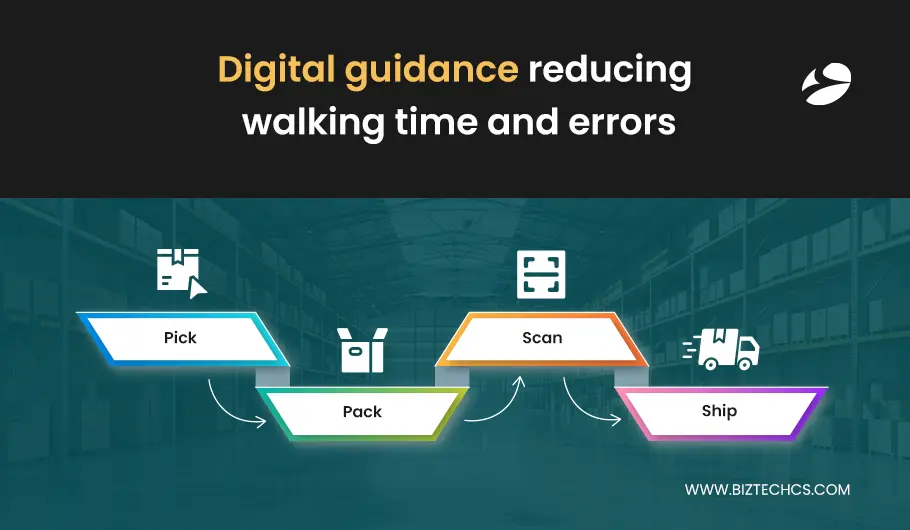

Enhanced Warehouse Efficiency

The system accelerates picking, packing, and shipping by walking warehouse workers through the process step-by-step. This minimizes mistakes and processes orders rapidly. Greater accuracy translates into fewer returns and increased customer satisfaction.

Warehouse operations become more streamlined and productive overall. The workload on workers is decreased by using this streamlined process. The warehouse can move more volume without extra stress.

Improved Inventory Accuracy

Real-time inventory tracking provides current stock data across multiple locations. This minimizes manual count errors and stale data. Proper records eliminate overstocking and stock shortages. Trust is increased between departments, and planning is enhanced as a result. The openness also facilitates faster responses to inventory problems. Odoo’s inventory management software maintains accurate and reliable data.

Cost Savings

Improved inventory control reduces the money tied up in overstock. Less manual intervention means fewer errors and less time on repetitive tasks. These savings accumulate in warehouse operations and procurement.

Not overstocking results in less storage space and fewer write-offs. Automation eliminates unnecessary costs and improves accuracy. Odoo ERP for manufacturing and inventory management directly adds to the bottom line.

Better Demand Planning

Odoo utilizes historical data to forecast demand, enabling the alignment of stock levels with customer needs. This planning reduces guesswork and improves purchasing decisions. Accurate forecasts prevent costly overstock and stockouts.

Businesses can respond more quickly and confidently to market changes. This leads to more efficient use of resources and happier customers. Demand planning becomes a reliable part of inventory management.

Seamless Integration

Odoo relies on historic data to predict demand, ensuring alignment of stock levels with customer demand. This planning minimizes guessing and enhances purchasing choices. Precise forecasts avoid expensive overstock and stockouts.

Companies can react more quickly to market trends with confidence. This results in better resource utilization and satisfied customers. Demand planning is an assured element of inventory management.

Executive Summary

A leading manufacturer of PVC-coated fabrics, widely used across industries such as architecture, lifestyle, sports, and transportation, was facing operational challenges. As the business grew, relying on Excel for managing production and inventory led to inefficiencies, errors, and bottlenecks. To resolve this, the company implemented Odoo ERP, integrating modules for manufacturing, inventory, quality, and sales. This helped streamline production, improve inventory management, and efficiently handle customer orders.

Business Challenges

Solutions Provided

Business Impact

Flexible Customization

Companies opt for Odoo ERP for inventory management due to its ability to mold itself to their specific requirements. Modules can be easily modified to meet the specific needs of a particular industry. This flexibility means that companies don’t need to transform their processes to accommodate the software.

Customization makes the system more efficient and applicable. Through Odoo ERP Customization, companies can configure workflows, fields, and automation rules to fit niche operational needs without compromise.

Rather, the software accommodates the way they already function. Customization makes the system more efficient and applicable. It also enables growth and modifications without compromising functionality.

Modular & Cost-effective

Odoo offers a pay-for-use system, allowing companies to only pay for what they use. This eliminates unnecessary costs that come with one-size-fits-all packages. Companies can begin with minimal initial requirements and develop features as they expand.

This makes Odoo ERP for manufacturing an affordable choice for both small and big companies. The modular architecture ensures less wastage and tighter budget control. It provides companies with the freedom to invest where it counts the most.

User-friendly Interface

Odoo inventory management is recognized for its minimalist and clean interface. Employees can easily learn to utilize the system with minimal training. An easy-to-use design minimizes errors and accelerates adoption on teams.

This translates to faster outcomes and less downtime during changeovers. Easy-to-navigate workflows enable users to concentrate on tasks, not the software. The more straightforward the tool, the better the daily operations flow.

Scalable Solution

As organizations expand, their systems must keep pace with them. Odoo expands comfortably from small businesses to large companies without compromise on performance. It is thus a suitable option for companies looking to plan for long-term expansion.

Whether expanding product offerings or locations, Odoo continues to grow. It supports greater data and users without stress. This scalability saves time and funds on future system upgrades.

End-to-End Integration

The Odoo ERP modules integrate Inventory with Sales, Purchasing, Manufacturing, and CRM, enabling the seamless flow of information across different departments. This integration prevents duplicate data entry and minimizes errors.

This ecosystem promotes faster business response to demand and streamlines the order-to-delivery process. With expert Odoo Integration services, businesses can ensure their departments stay in sync while eliminating silos.

When teams work together on the same platform, coordination occurs smoothly. This ecosystem promotes faster business response to demand and streamlines the order-to-delivery process.

Inventory management must be carried out properly so that operations run smoothly and customers are satisfied. Manufacturing industries can achieve better stock levels and enhanced warehouse efficiency control with Odoo ERP.

Automations increase efficiency, reduce stockouts, and enhance accuracy, ultimately lowering costs. Departments that receive data in real-time and have integrated modules can operate together without delay or error, resulting in smarter and less disruptive decisions within the supply chain.

Odoo-supported inventory and warehouse process optimization provides a launchpad for consistent growth and trust-building with customers. Contact BiztechCS for a custom demonstration or consultation that suits your requirements to see how these advantages can synergize with your business.

Inventory inefficiencies, stockouts, and unproductive warehouses can quickly erode your margin. Odoo ERP helps solve exactly these kinds of problems for manufacturers and distributors by building streamlined and real-time inventory ecosystems that fulfill and directly reduce operational waste.

Here’s how we do it:

At BiztechCS, we configure the Odoo Inventory module to ensure your stock is always visible. From raw materials to semi-finished products or finished goods, you see it all in one place.

Centralized, real-time dashboards disclose inventory levels across various locations, keeping you informed at any time. Hence, you can track your stock without having to wait around for reports.

We have also established multi-warehouse support with well-defined location hierarchies to maintain order. Alongside this, mobile barcode scanning has been implemented for swift and error-free stock updates while on the move.

Overstocking and stockout situations can be avoided by utilizing automated replenishment flows, which we help you set up. These flows use minimum and maximum stock rules specific to each product. Upon reaching the set stock levels, Odoo automatically triggers purchase orders or production orders.

Forecasting tools are also configured to accommodate seasonal variations and supplier lead times, ensuring your inventory aligns with actual demand. These intelligent features keep your supply chain smooth, balanced, and highly reactive.

At BiztechCS, all processes related to warehouse operations are handled, from inbound receipts to outbound shipments. Intelligent routing is implemented to guide the staff efficiently through picking and batch handling.

Automated putaway and picking methods reduce time wasted searching for items. FIFO, LIFO, or zoned-location-based rules can be used for orderly storage and traceability. The integration of barcode devices tracks stock movements in real-time, and at this level, tracking optimizes accuracy and speeds up all warehouse processes.

Whether it’s setting up intelligent replenishment workflows or enabling multi-location tracking, our team ensures a smooth rollout. This is made possible through our deep expertise in Odoo ERP software development, tailored specifically to your inventory challenges.

All product and company names are trademarks™, registered® or copyright© trademarks of their respective holders. Use of them does not imply any affiliation with or endorsement by them.